The Interior Fantastic thing about Primary Electronics

[ad_1]

Eric Schlaepfer was making an attempt to repair a damaged piece of take a look at tools when he got here throughout the reason for the issue—a troubled tantalum capacitor. The element had in some way shorted out, and he wished to know why. So he polished it down for a glance inside. He by no means discovered the supply of the brief, however he and his collaborator, Windell H. Oskay, found one thing even higher: a wide ranging hidden world inside electronics. What adopted had been hours and hours of sharpening, cleansing, and images that resulted in Open Circuits: The Interior Fantastic thing about Digital Elements (No Starch Press, 2022), an excerpt of which follows. Because the authors write, every part about these parts is intentionally designed to satisfy particular technical wants, however that design results in “unintentional magnificence: the emergent aesthetics of stuff you had been by no means anticipated to see.”

From a e book that spans the vast world of electronics, what we at

IEEE Spectrum discovered surprisingly compelling had been the insides of issues we don’t spend a lot time enthusiastic about, passive parts. Transistors, LEDs, and different semiconductors could also be the place the motion is, however the easy physics of resistors, capacitors, and inductors have their very own kind of splendor.

Excessive-Stability Movie Resistor

This high-stability movie resistor, about 4 millimeters in diameter, is made in a lot the identical means as its cheap carbon-film cousin, however with exacting precision. A ceramic rod is coated with a advantageous layer of resistive movie (skinny steel, steel oxide, or carbon) after which a superbly uniform helical groove is machined into the movie.

As a substitute of coating the resistor with an epoxy, it’s hermetically sealed in a lustrous little glass envelope. This makes the resistor extra strong, supreme for specialised instances equivalent to precision reference instrumentation, the place long-term stability of the resistor is vital. The glass envelope offers higher isolation in opposition to moisture and different environmental modifications than customary coatings like epoxy.

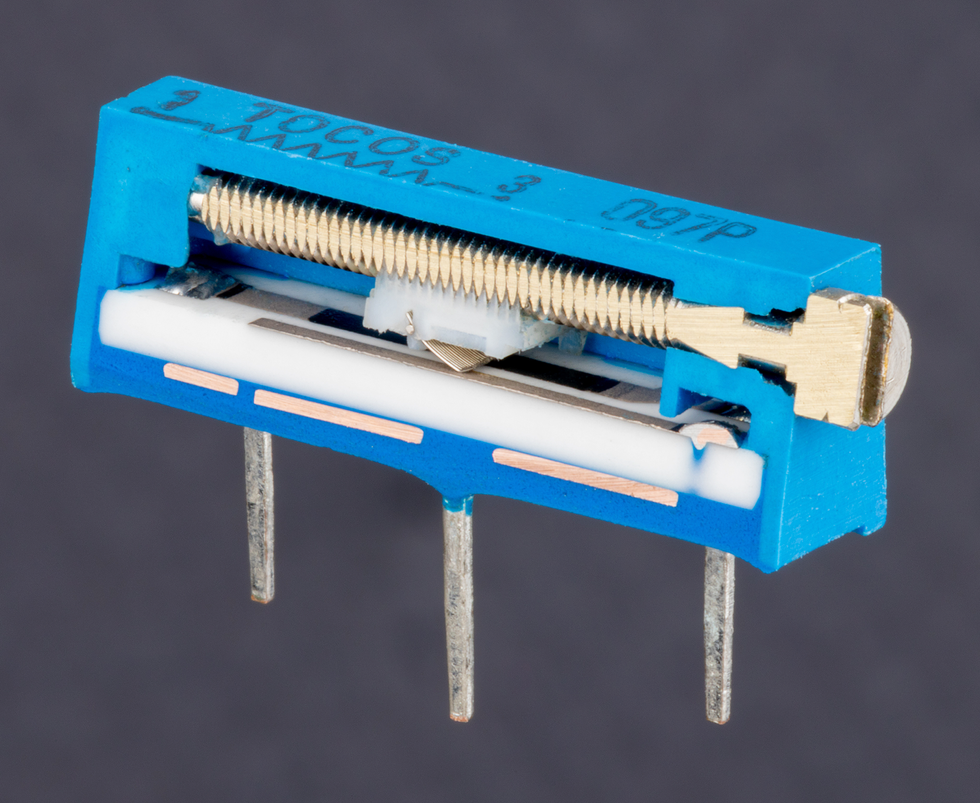

15-Flip Trimmer Potentiometer

It takes 15 rotations of an adjustment screw to maneuver a 15-turn trimmer potentiometer from one finish of its resistive vary to the opposite. Circuits that have to be adjusted with advantageous decision management use such a trimmer pot as an alternative of the single-turn selection.

The resistive aspect on this trimmer is a strip of cermet—a composite of ceramic and steel—silk-screened on a white ceramic substrate. Display-printed steel hyperlinks every finish of the strip to the connecting wires. It’s a flattened, linear model of the horseshoe-shaped resistive aspect in single-turn trimmers.

Turning the adjustment screw strikes a plastic slider alongside a monitor. The wiper is a spring finger, a spring-loaded steel contact, connected to the slider. It makes contact between a steel strip and the chosen level on the strip of resistive movie.

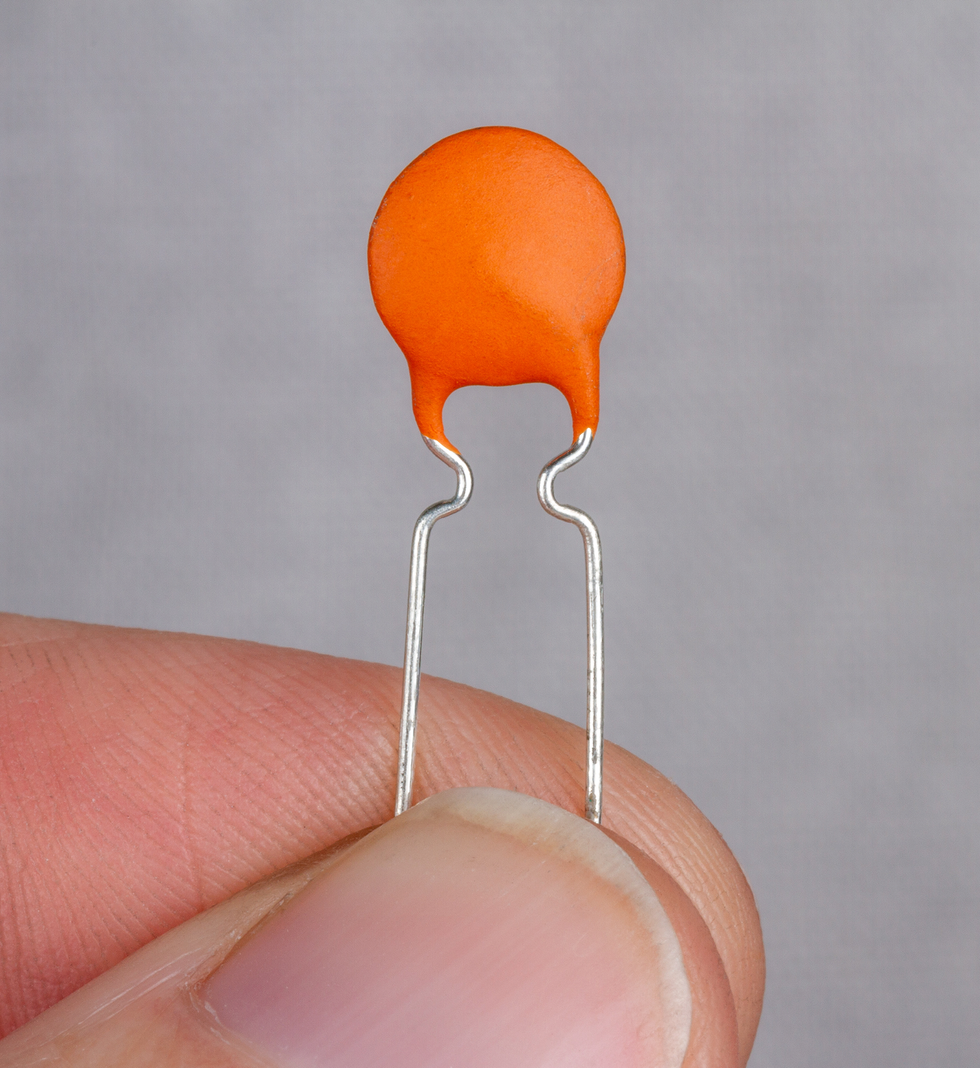

Ceramic Disc Capacitor

Capacitors are basic digital parts that retailer power within the type of static electrical energy. They’re utilized in numerous methods, together with for bulk power storage, to clean out digital alerts, and as laptop reminiscence cells. The only capacitor consists of two parallel steel plates with a niche between them, however capacitors can take many types as long as there are two conductive surfaces, referred to as electrodes, separated by an insulator.

A ceramic disc capacitor is a low-cost capacitor that’s regularly present in home equipment and toys. Its insulator is a ceramic disc, and its two parallel plates are extraordinarily skinny steel coatings which are evaporated or sputtered onto the disc’s outer surfaces. Connecting wires are connected utilizing solder, and the entire meeting is dipped right into a porous coating materials that dries arduous and protects the capacitor from injury.

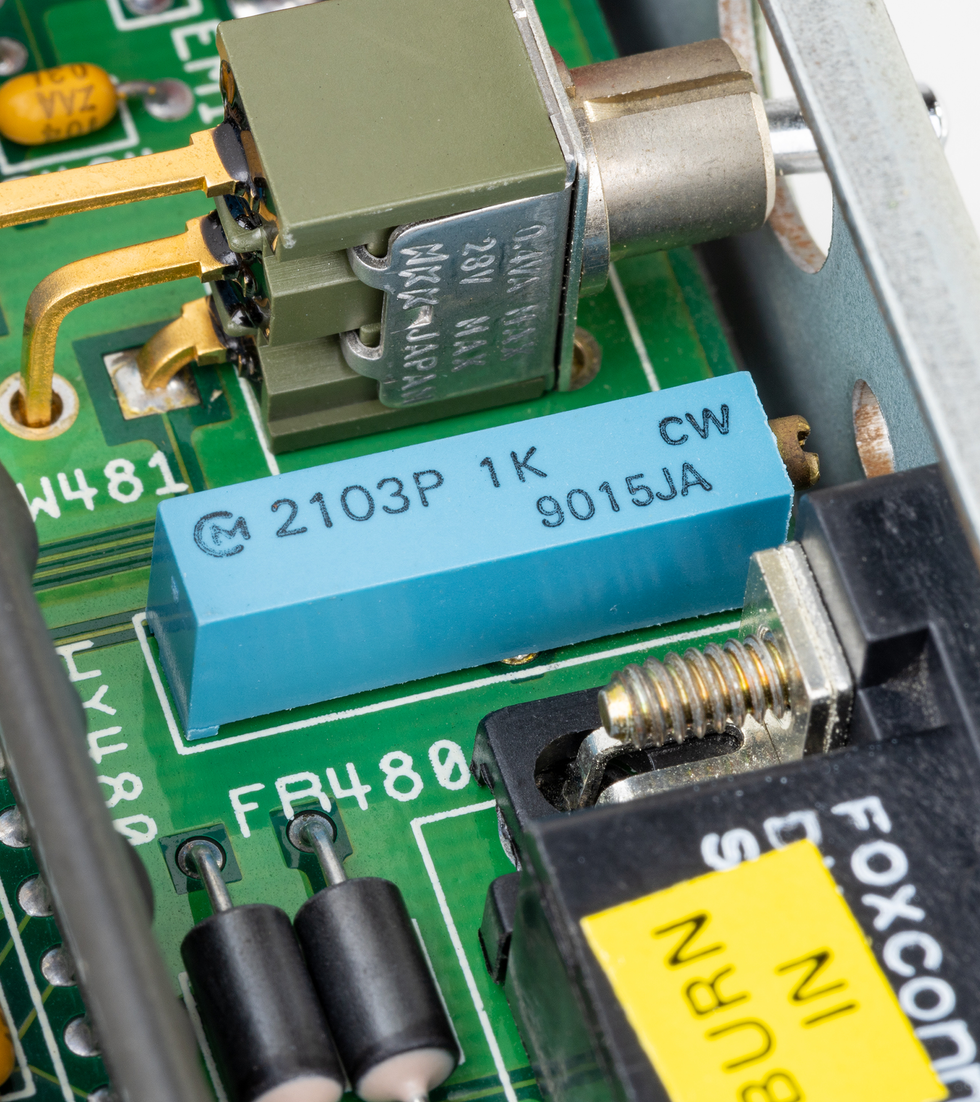

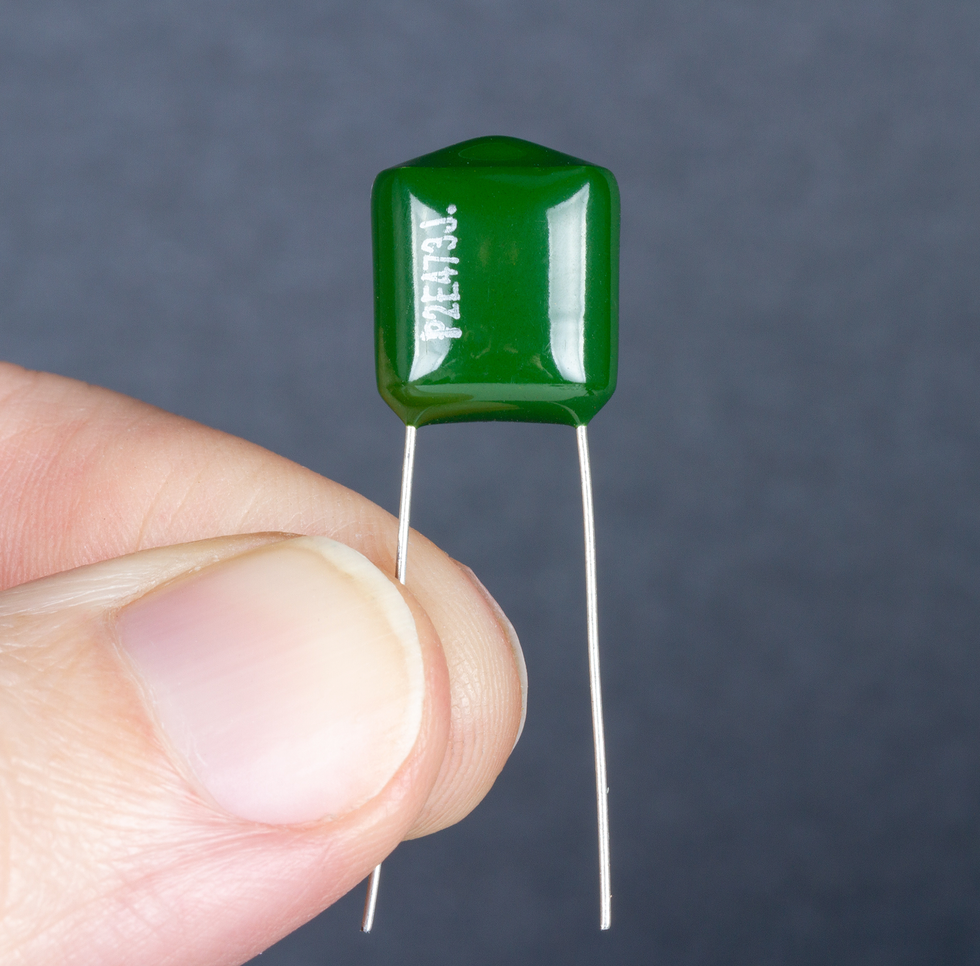

Movie Capacitor

Movie capacitors are regularly present in high-quality audio tools, equivalent to headphone amplifiers, file gamers, graphic equalizers, and radio tuners. Their key characteristic is that the dielectric materials is a plastic movie, equivalent to polyester or polypropylene.

The steel electrodes of this movie capacitor are vacuum-deposited on the surfaces of lengthy strips of plastic movie. After the leads are connected, the movies are rolled up and dipped into an epoxy that binds the meeting collectively. Then the finished meeting is dipped in a tricky outer coating and marked with its worth.

Different kinds of movie capacitors are made by stacking flat layers of metallized plastic movie, slightly than rolling up layers of movie.

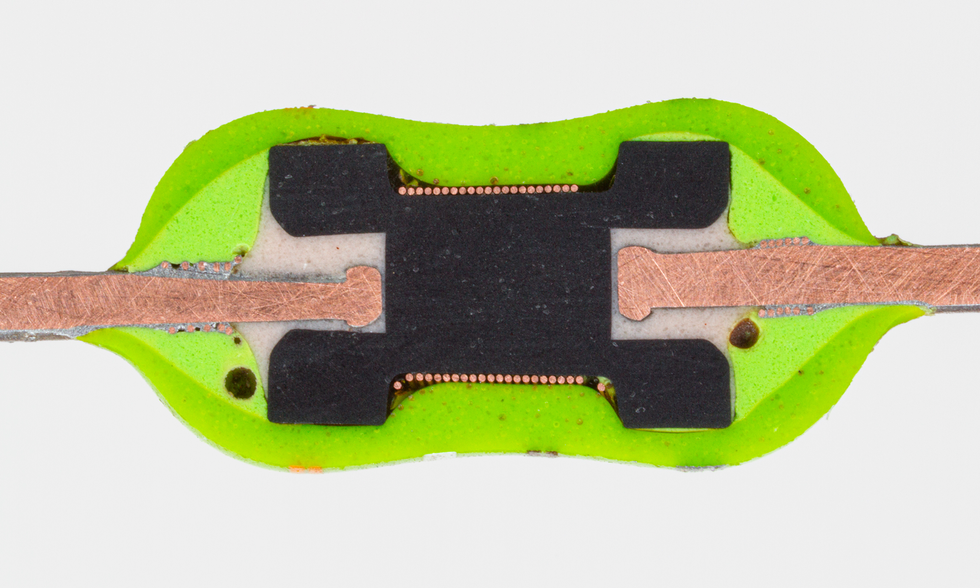

Dipped Tantalum Capacitor

On the core of this capacitor is a porous pellet of tantalum steel. The pellet is comprised of tantalum powder and sintered, or compressed at a excessive temperature, right into a dense, spongelike stable.

Similar to a kitchen sponge, the ensuing pellet has a excessive floor space per unit quantity. The pellet is then anodized, creating an insulating oxide layer with an equally excessive floor space. This course of packs quite a lot of capacitance right into a compact system, utilizing spongelike geometry slightly than the stacked or rolled layers that the majority different capacitors use.

The system’s optimistic terminal, or anode, is related on to the tantalum steel. The detrimental terminal, or cathode, is shaped by a skinny layer of conductive manganese dioxide coating the pellet.

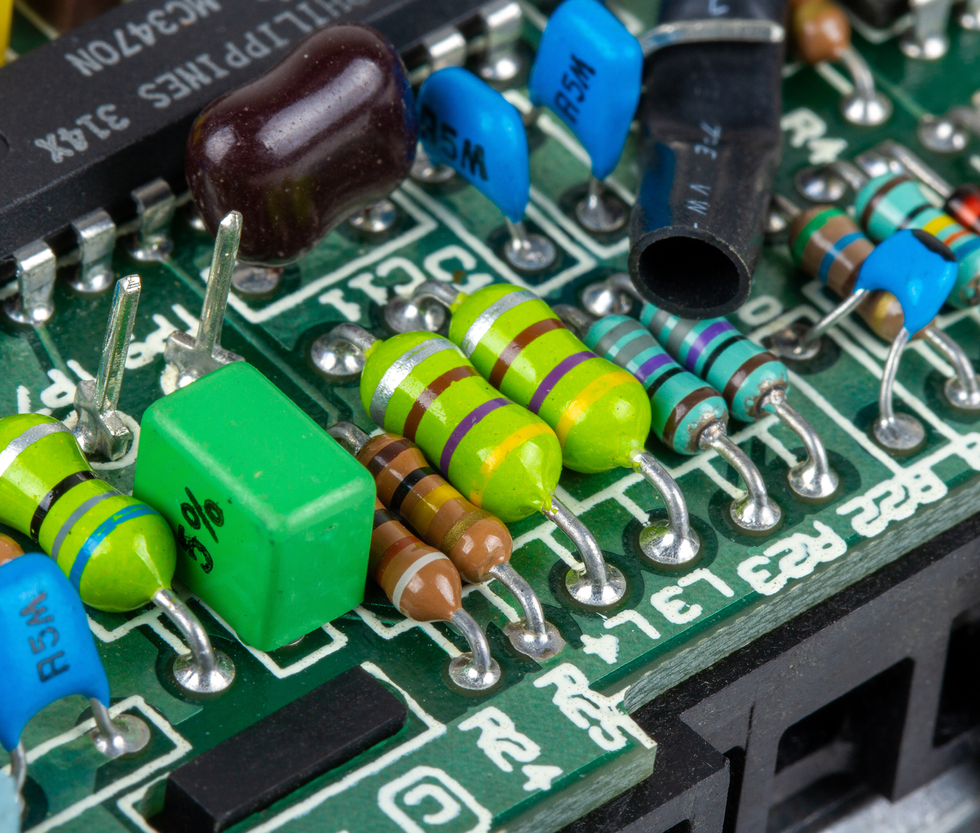

Axial Inductor

Inductors are basic digital parts that retailer power within the type of a magnetic area. They’re used, for instance, in some kinds of energy provides to transform between voltages by alternately storing and releasing power. This energy-efficient design helps maximize the battery lifetime of cellphones and different moveable electronics.

Inductors usually encompass a coil of insulated wire wrapped round a core of magnetic materials like iron or ferrite, a ceramic crammed with iron oxide. Present flowing across the core produces a magnetic area that acts as a kind of flywheel for present, smoothing out modifications within the present because it flows by way of the inductor.

This axial inductor has quite a few turns of varnished copper wire wrapped round a ferrite kind and soldered to copper leads on its two ends. It has a number of layers of safety: a transparent varnish over the windings, a light-green coating across the solder joints, and a putting inexperienced outer coating to guard the entire element and supply a floor for the colourful stripes that point out its inductance worth.

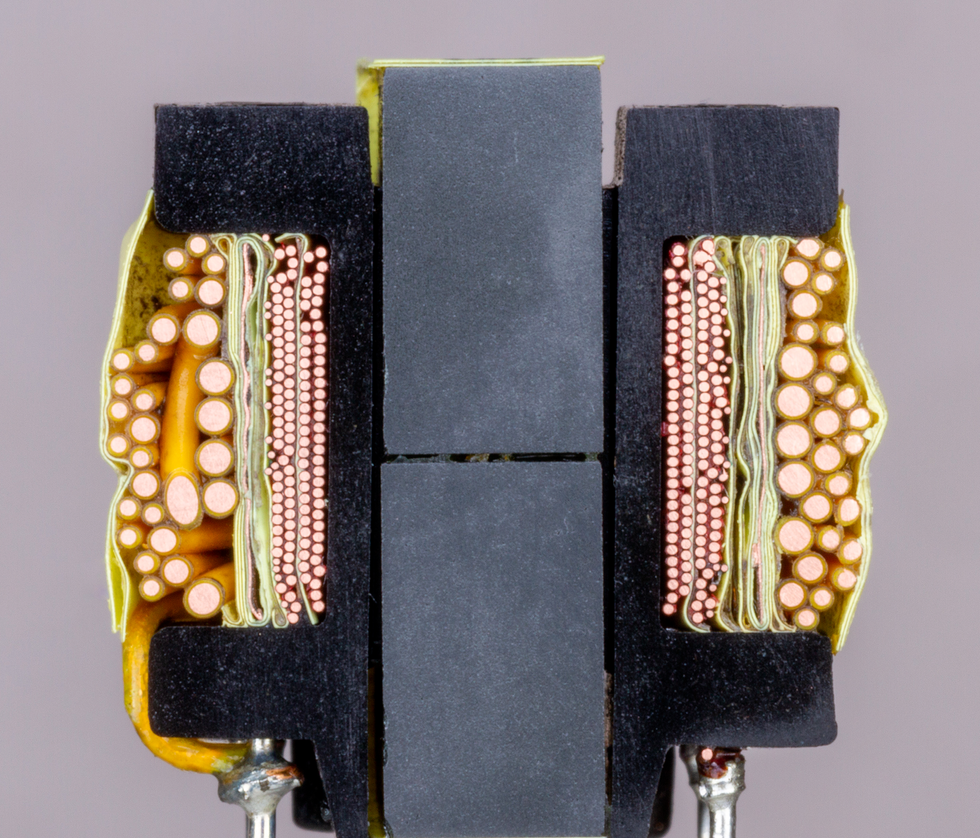

Energy Provide Transformer

This transformer has a number of units of windings and is utilized in an influence provide to create a number of output AC voltages from a single AC enter equivalent to a wall outlet.

The small wires nearer the middle are “excessive impedance” turns of magnet wire. These windings carry the next voltage however a decrease present. They’re protected by a number of layers of tape, a copper-foil electrostatic defend, and extra tape.

The outer “low impedance” windings are made with thicker insulated wire and fewer turns. They deal with a decrease voltage however the next present.

All the windings are wrapped round a black plastic bobbin. Two items of ferrite ceramic are bonded collectively to kind the magnetic core on the coronary heart of the transformer.

[ad_2]

No Comment! Be the first one.